Semiconductor Industry Services

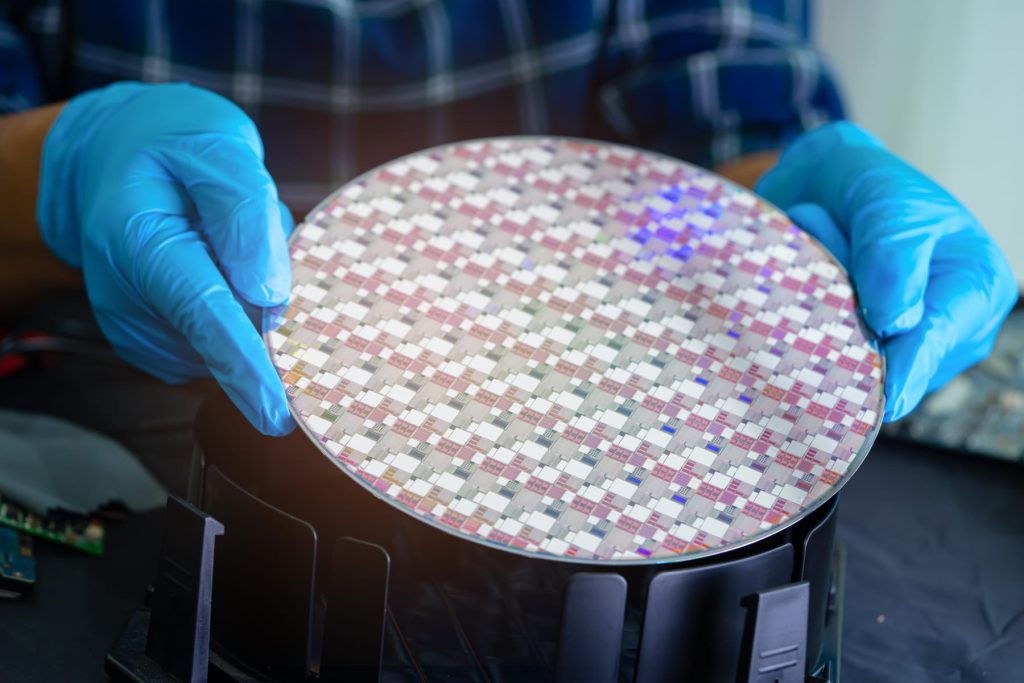

In semiconductor manufacturing, precision isn’t a goal—it’s a requirement.

Tillson Industrial provides cleanroom-compliant mechanical services for tool installs, subfab support, and utility tie-ins in high-tech fabs across the U.S.

Whether you’re standing up a new line, upgrading toolsets, or maintaining utility systems, we deploy millwrights trained for micro-tolerances, contamination control, and schedule-sensitive work.

Precision Millwright Services for High-Tech Manufacturing

We understand the operational rigor of advanced fabs. Our crews work in compliance with ISO cleanroom standards and follow documented protocols for vibration isolation, non-contaminating materials, and tightly controlled rigging and torque sequences.

We support the mechanical side of:

- CMP, lithography, etch, metrology, and deposition tools

- Utility skids (vacuum, exhaust, chiller, DI water, CDA, N₂, process gases)

- Subfab support systems and risers

- Equipment moves, replacements, and upgrades

- Skid-to-skid alignments and mechanical tie-ins

What We Do for Semiconductor Clients

1. Cleanroom Equipment Installation

We set process tools and fab equipment with laser-level accuracy. We install vibration isolation mounts, shim and level baseplates, and torque to OEM spec.

2. Subfab Rigging & Placement

Our teams install and align utility skids, vacuum pumps, scrubbers, exhaust systems, and gas cabinets—below clean zones and under airflow protection.

3. Mechanical Utility Tie-Ins

We connect equipment to mechanical lines—DI water, CDA, chilled water, exhaust, and drain—using vibration-damped fittings, torque-certified hardware, and flex supports.

4. Grouting & Base Prep

We install Chockfast epoxy grout under heavy subfab equipment, verify anchor torque, and prep foundations for long-term alignment and vibration isolation.

5. Laser Alignment & System Validation

We laser-align shafts, verify DBSE, and correct soft foot or anchor misalignment. We provide full documentation for QA, commissioning, or requalification teams.

6. Precision Equipment Moves

Tool relocations are high-risk. We rig, transport, re-set, and align fab tools without disrupting adjacent lines, airflow, or clean zones.

Why Fab Operators Choose Tillson

Because every spec, surface, and second matters.

Tillson operates like a surgical unit inside your fab—trained, tool-qualified, and documentation-driven. We’ve helped bring fabs online ahead of schedule, corrected catastrophic misalignments before startup, and executed utility tie-ins without a single particle out of place.

Our Cleanroom Commitments:

- ISO cleanroom apparel compliance

- Non-contaminating rigging gear

- Zero-particle protocols

- Final alignment and torque reporting

- Coordination with tool OEMs and facility teams

- Equipment ID and layout verification

Where We Work

- 300mm and 200mm semiconductor fabs

- Advanced logic and memory manufacturing plants

- Foundry expansion sites

- R&D and pilot fabs

- Equipment upgrade and decommissioning projects

- Utility corridors and subfab zones