Rigging Services

When failure isn't an option, every lift has to be perfect.

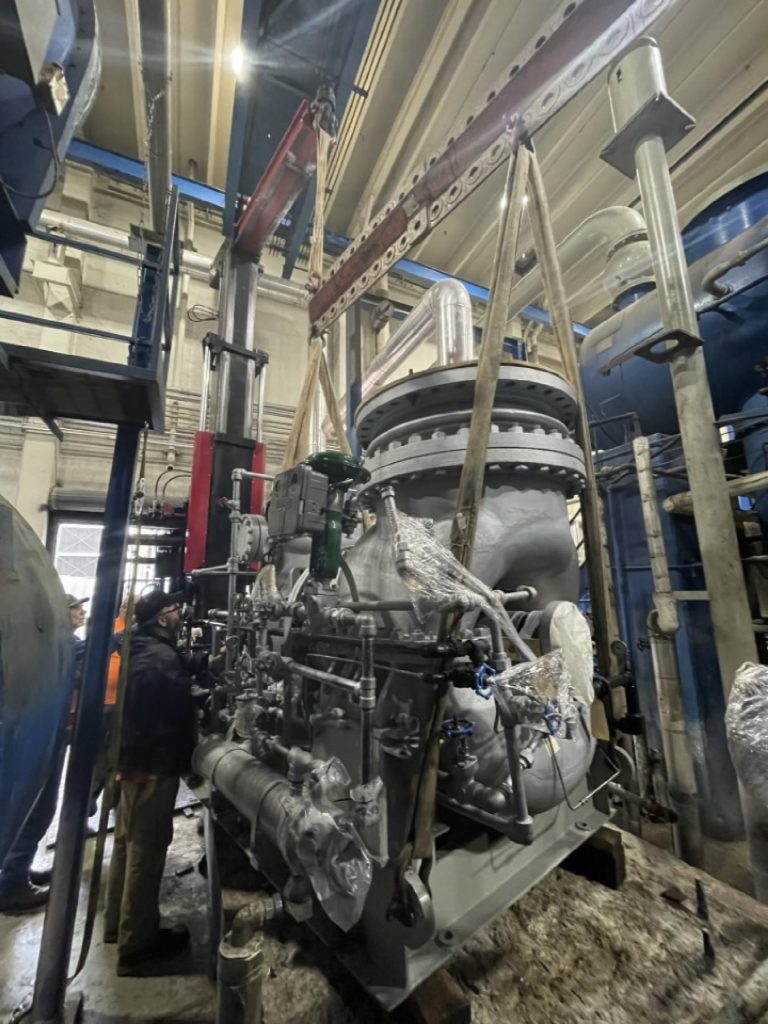

Rigging is more than moving equipment—it’s protecting performance, timelines, and team safety with every hoist. At Tillson Industrial, our rigging crews are millwright-trained, field-tested, and trusted to move heavy, high-value assets in some of the most demanding industrial environments in the country.

What We Do

We provide turnkey rigging and equipment movement services for industrial clients who need precision handling, tight-space maneuvering, and zero room for error. Whether it’s a 40,000 lb. compressor or a subfab cleanroom tool, we lift, move, and set it right—the first time.

We handle:

- Compressors, pumps, turbines, and gearboxes

- Motors, fans, MCCs, and mechanical skids

- Skid packages and modular process units

- Vertical/horizontal lifts in confined plant spaces

- Moves between bays, pads, and staging areas

- Foundation setting, replacement, and reinstallation

Whether it’s across the plant or across the country—we handle the heavy lifting so you don’t have to.

Why It Matters

One bad lift can break more than equipment.

Improper rigging puts your project, schedule, and personnel at risk. Damaged gearboxes, bent shafts, cracked bases, or worse—an injury on-site. And yet, too many contractors still treat rigging as just another line item. We don’t.

What we prevent:

- Load imbalance and tip-over

- Equipment shock, bend, or impact damage

- Soft foot caused by flexed or twisted frames

- Anchor shear or base distortion

- Delays due to clearance miscalculation or inadequate tooling

Our crews don’t improvise—we plan. Every lift is engineered. Every move is controlled. Every outcome is intentional.

How We Get It Done

1. Pre-Lift Planning

We assess the equipment’s weight, geometry, center of gravity, clearances, rigging points, and environmental constraints. We map the route, identify obstacles, and establish control zones.

2. Lift Plan & Gear Selection

We select the right combination of cranes, gantries, dollies, slings, toe jacks, and tag lines. Our plans define angles, sling load limits, and crew roles. Plans and JSAs are reviewed with your team and site safety leads.

3. Rigging Execution

We rig and lift with precision—no snap decisions, no guesswork. Moves are performed under full control, with active communication and coordinated pacing. Temporary supports or staging platforms are installed if needed.

4. Placement & Anchoring

Once equipment is moved, we handle setting, shimming, leveling, and anchoring. If required, we prepare the base for grout and coordinate with alignment crews for final setup.

5. Closeout & Handoff

We walk the job down with your team, verify install position, and provide any lift reports, torque logs, or field documentation required for turnover or compliance.

Rigging Services We Offer

- Equipment installation and relocation

- Heavy equipment and crane rigging

- Hoisting and confined-space movement

- Equipment disassembly and reassembly

- Structural skid positioning and modular installs

- Foundation placement and removal support

- Emergency lift and recovery services

If it needs to move—we make it happen. Safely. Reliably. Efficiently.

Where We Work

Tillson crews perform rigging work at:

- Refineries and chemical processing plants

- Power plants and energy generation facilities

- Water/wastewater treatment sites and lift stations

- Manufacturing, packaging, and material recovery facilities (MRFs)

- Ports, terminals, and field project sites

From cleanrooms to midstream—if the space is tight and the asset is critical, we’ve been there.

The Tillson Standard

We don’t gamble with weight, safety, or timelines.

\Your equipment is valuable, your schedule is tight, and your plant can’t afford a misstep. That’s why every rigging job we take on is done by pros who’ve seen it all—and planned for worse.

Call Tillson when it’s time to move the immovable.