Industrial Alignment Services

Every time a pump runs out of spec, a motor fights soft foot, or a coupling bears uneven load, you're stacking up downtime, failure points, and repair bills.

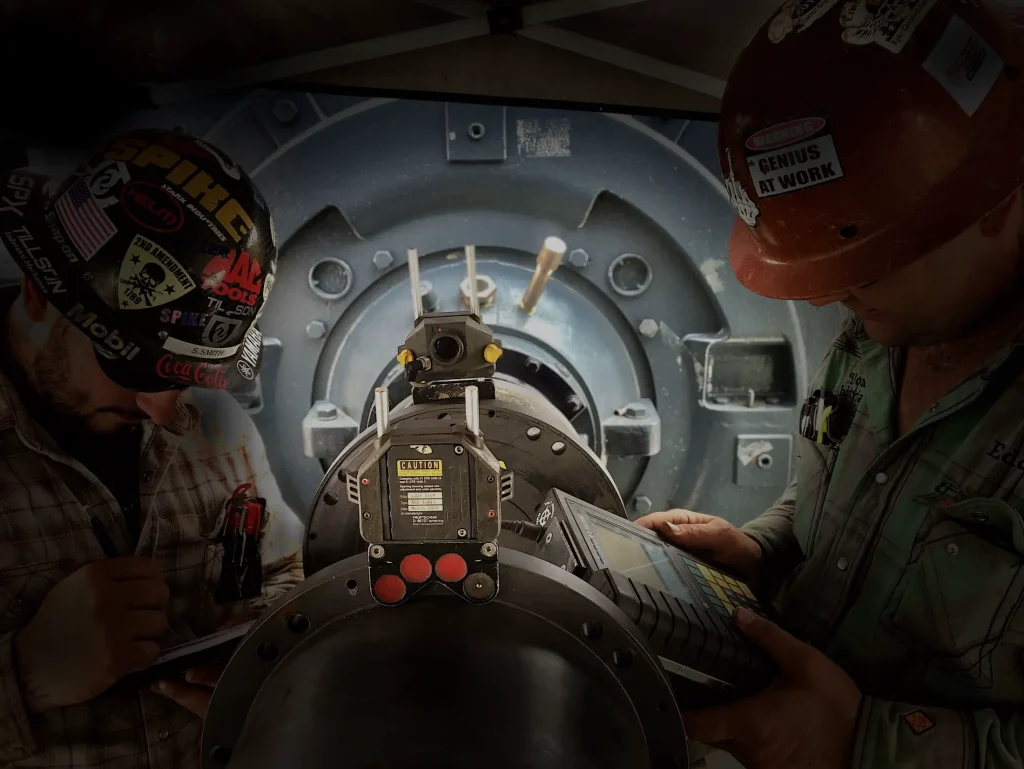

At Tillson Industrial, we specialize in precision shaft alignment and corrective base work for industrial rotating equipment—ensuring your systems run straighter, quieter, and longer.

What We Do

We provide high-accuracy laser alignment and mechanical adjustment services for rotating and driven systems. Our crews don’t eyeball it or leave it “close enough”—we use laser instrumentation and API 686 standards to ensure your equipment is installed and operating at exacting tolerances.

We align:

- Motors to pumps, compressors, and gearboxes

- Horizontal and vertical shaft equipment

- Belt-driven and sheave systems

- Spacer couplings, flex joints, gear couplings

- Skid-to-skid and multi-element systems

- DBSE targets and thermal offsets

If it spins, connects, or transmits torque—we make sure it’s aligned to perform.

Why It Matters

Misalignment is the silent killer of industrial systems.

A small offset—barely visible to the eye—can lead to cascading failures:

- Bearing wear

- Seal leaks

- Shaft fatigue

- Vibration-induced damage

- Elevated power consumption

- Emergency shutdowns

Over time, these add up to reduced equipment life, higher energy costs, and production loss. Worse, misalignment in one component often creates issues in others—multiplying your repair budget and risking your schedule.

Proper alignment leads to:

- Extended life of rotating elements

- Reduced vibration and noise

- Lower electrical and mechanical load

- Fewer unplanned outages

- Compliance with OEM, ANSI, and API 686 specs

Alignment isn’t just a maintenance task—it’s a reliability strategy.

How We Get It Done

1. Baseline Inspection

We start with a full mechanical assessment: checking soft foot, pipe strain, thermal expansion effects, and overall system geometry. We record initial DBSE (Distance Between Shaft Ends) and alignment targets.

2. Laser Alignment Setup

Using industry-leading laser systems, we measure shaft offsets and angular deviations down to .001″–.002″ TIR. We don’t just match flanges—we dial in rotational accuracy across all planes.

3. Mechanical Correction

We shim, adjust, or re-level your motor, pump, or driven load to eliminate misalignment and ensure thermal growth offsets are accounted for—especially on high-temperature or high-speed equipment.

4. Final Validation & Reporting

You receive a detailed before/after report showing alignment corrections, shim changes, and tolerance results. We also log DBSE, soft foot data, and coupling condition for future reference.

Optional Services:

- Base repairs and epoxy grouting

- Skid adjustments and pedestal rework

- Long-term alignment monitoring

What Is Equipment Alignment?

Alignment means matching the rotational centerlines of connected machines—typically a motor and a pump, or a gearbox and a fan—so that the system runs true.

Think of it like wheel alignment on a car: if things are even slightly off, you get vibration, component damage, and poor efficiency. Industrial systems work the same way—but with more horsepower, more torque, and a lot more at stake.

Misalignment leads to:

- Early seal and bearing failure

- Increased vibration and heat

- Premature equipment wear

- Reduced overall system life

Proper alignment keeps systems:

- Running smoother

- Lasting longer

- Operating more efficiently

Where We Work

Tillson’s alignment services are deployed across:

- Refineries and chemical plants

- Power generation and utility infrastructure

- Water and wastewater treatment

- Manufacturing, packaging, and food processing

- Marine terminals and pump stations

- Fabrication shops and field startup projects

Wherever precision matters, we’re there.

The Tillson Guarantee

Alignment isn’t guesswork—it’s math, mechanics, and mastery.

At Tillson, we don’t “get it close.” We get it right. Every shim, every bolt, every offset—verified and documented. If your rotating systems are underperforming or showing signs of stress, misalignment is often the culprit. We’re here to fix it at the source.

Don’t wait for seals to fail. Call us before it costs you.