Industrial Compressor Services

These machines are critical to your facility’s operations. If they’re misaligned, under-supported, or allowed to vibrate unchecked, the failure won’t be small—or cheap.

At Tillson Industrial, we install, rebuild, and maintain compressors with exacting mechanical standards to eliminate the risk before it becomes a repair ticket.

What We Do

We provide full-scope field and shop services for reciprocating, screw, and centrifugal compressors. Whether you’re commissioning a new unit, handling a scheduled outage, or facing an emergency failure, we restore performance by rebuilding your system to meet—or exceed—OEM mechanical specs.

We support:

- Skid-mounted and standalone packages

- Air, gas, and process service compressors

- Engine- or motor-driven systems

- Horizontal, vertical, and specialty configurations

From vibration diagnostics to final torque checks, we handle the full mechanical scope so your compressor runs as designed—quiet, efficient, and aligned.

Why It Matters

Compressors fail hard—and fast—when they’re not mechanically right. They’re sensitive to even minor base distortion, coupling misfit, or thermal expansion misalignment.

And because they usually run continuous duty, issues compound quickly and take down everything downstream.

Common failure risks:

- Misalignment leading to bearing and seal failure

- Excessive vibration damaging piping and mounting surfaces

- Loose bases, cracked grout, or sheared anchor bolts

- Coupling stress and shaft deflection

- Loss of throughput or efficiency

If your compressor system is underperforming, our mechanical team can isolate the root cause, correct it, and return the system to spec.

How We Get It Done

1. Inspection & Vibration Check

We start with a full inspection of the compressor, skid, and base. Using vibration analysis and visual diagnostics, we identify component wear, alignment issues, or system strain.

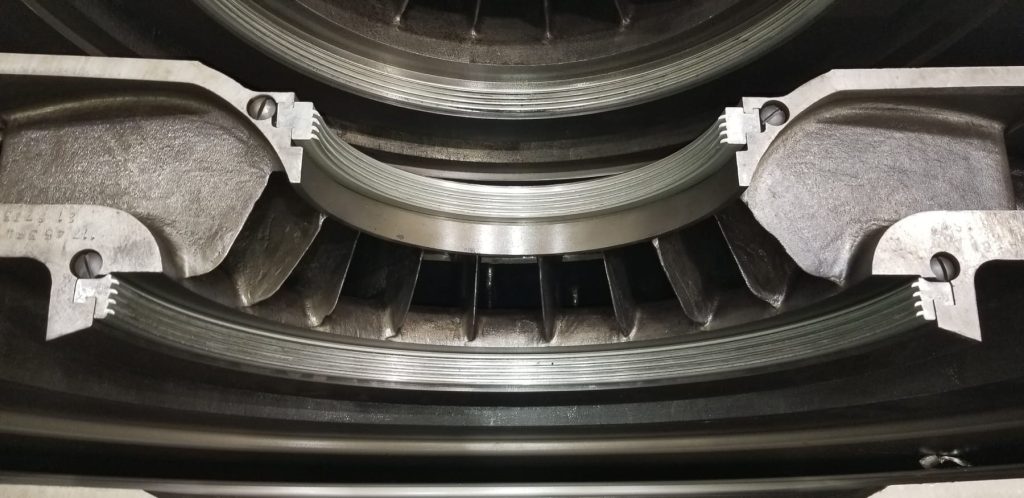

2. Mechanical Teardown & Cleaning

We remove housings, seals, bearings, shafts, and internal components. Every part is cleaned, evaluated, and measured against spec to determine what needs to be replaced.

3. Rebuild & Component Replacement

We install new bearings, seals, gaskets, and hardware. Where needed, we machine mating surfaces, sleeve worn shafts, or reinforce bearing journals to extend lifecycle performance.

4. Base Prep & Alignment

We regrout or reinforce the base as needed. Units are laser-aligned to drivers (motor or engine) and DBSE (Distance Between Shaft Ends) is verified. All anchor bolts are torqued to spec.

5. Reassembly & Final Checks

Once rebuilt, we reassemble the compressor, balance the rotor (if applicable), and document tolerances. Pipe strain is relieved, soft foot is corrected, and we prep the unit for restart.

6. Startup & Commissioning Support

Our team remains on-site or on-call to assist with system pressurization, startup verification, and torque/alignment confirmation. You get a final service report with findings and actions taken.

Systems We Support

We service compressors in:

- Refineries and petrochemical facilities

- Chemical and gas processing plants

- Power generation and cogeneration sites

- Manufacturing and food processing plants

- Water, wastewater, and utility facilities

If it compresses, moves, or seals gas—we’ve handled it.

The Tillson Commitment

We don’t bandage compressors—we fix them for good. Our mechanical rebuilds are engineered for uptime and accountability. We’re not here to “get it spinning.” We’re here to restore your system to spec, so it runs without surprise failures, emergency shutdowns, or unnecessary maintenance.

Call Tillson when your compressor needs more than a parts swap—it needs a precision rebuild.