Industrial Gearbox Services

Tillson Industrial delivers field and shop-based gearbox services designed to restore power transmission, eliminate vibration, and extend the life of your entire drive system.

Whether you’re running a critical process line or a remote pump station, we make sure your gearbox stays in the fight.

What We Do

We provide full-scope gearbox overhaul, maintenance, and repair services across industries that depend on mechanical uptime.

From minor seal swaps to complete teardown, rebuild, and reinstallation, our teams work to OEM tolerances with zero shortcuts.

We service:

- Parallel shaft gearboxes

- Planetary and right-angle drives

- Industrial reducers and speed increasers

- Gearboxes on fans, pumps, conveyors, mixers, blowers

- Units from Falk, Flender, SEW-Eurodrive, Sumitomo, Rexnord, Hansen, and more

If it’s turning torque, we’ve worked on it.

Why It Matters

When gearboxes fail, it’s never just the gearbox.

Left unresolved, minor issues like seal leaks or bearing noise turn into full system outages. Worse, they can damage connected motors, drive shafts, or foundation bases. That’s why we don’t patch problems—we resolve root causes.

We eliminate:

- Excessive backlash or worn gear teeth

- Shaft misalignment and vibration

- Seal leaks and lubricant contamination

- Cracked housings and base distortion

- Soft foot and pipe strain at install

Your gearbox isn’t just a component—it’s the heart of your torque delivery. We treat it that way.

How We Get It Done

1. Inspection & Diagnosis

We begin with a shaft and oil condition inspection. We check for contamination, heat scoring, tooth wear, and preload issues. Runout and vibration readings are taken if the unit is still online.

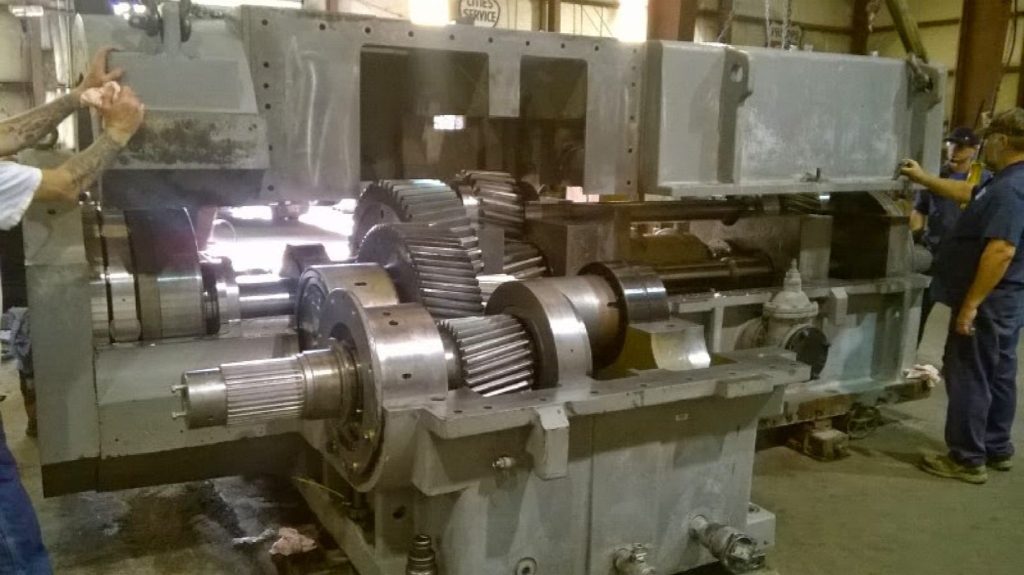

2. Disassembly & Cleaning

Gearbox is carefully opened in field or shop conditions. We remove gears, shafts, seals, bearings, and inspect all contact surfaces for pitting, scoring, or deflection.

3. Component Replacement

We replace bearings, seals, gaskets, and any damaged gearsets. When needed, we machine or sleeve shafts, clean threads, and correct housing fits.

4. Rebuild & Reinstall

Unit is reassembled with precision—torqued to spec, oil-clearance checked, and shafts aligned. In the field, we laser-align to motor or driven load, correcting for DBSE and thermal offsets.

5. Final Validation

We conduct rotation tests, check for abnormal noise or heat, verify anchor bolt torque, and complete final documentation with before/after specs.

Field or Shop—We’ve Got You Covered

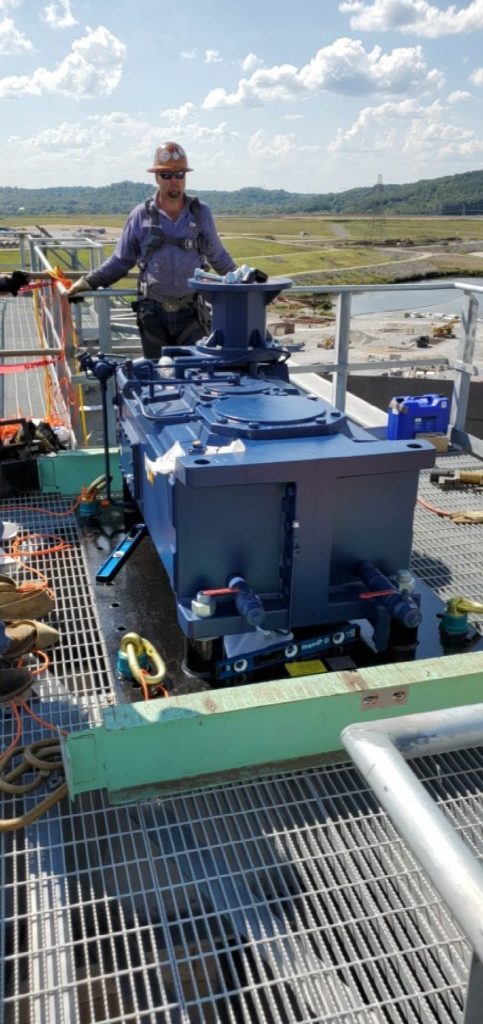

- In-Field Repairs – We rebuild gearboxes in place during shutdowns or on tight schedules

- Shop Overhauls – Full tear-down, sandblasting, machining, and repainting as needed

- Emergency Swaps – Remove, replace, and re-align critical drives with minimum delay

- Installation Support – Anchor setting, base grouting, laser alignment, and commissioning

Wherever your gearbox is, we’ll meet it there—with tools in hand and the fix in mind.

Where We Work

Our gearbox crews are trusted at:

- Refineries and chemical process plants

- Food and beverage production lines

- Pulp, paper, and packaging facilities

- Power generation and utility stations

- Material recovery, grain, and mining operations

- Water/wastewater treatment and pump stations

From conveyors to cooling towers—if it drives your process, we keep it running.

The Tillson Standard

We don’t rebuild for now. We rebuild for next time.

Because patch jobs don’t last. Our crews inspect, repair, and realign every gearbox like the entire system depends on it—because it does. No cut corners. No half-fixes. Just proven work that holds up under pressure.

Call Tillson when you’re done replacing the same gearbox twice.