Industrial Turbine Services

When you’re working with multi-stage steam units or high-speed gas turbines, everything from rotor position to flange torque matters.

One mechanical misstep can destroy a million-dollar machine. At Tillson Industrial, we provide field turbine services with the precision and discipline these systems demand.

What We Do

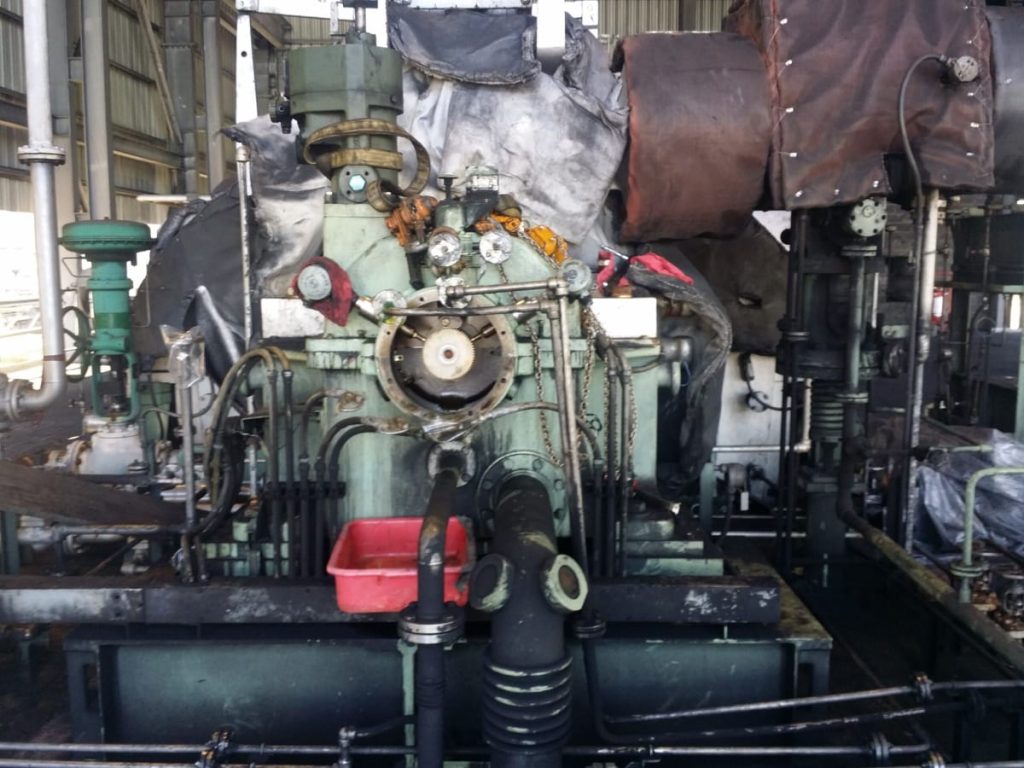

We perform mechanical field services for steam and gas turbines, including complete disassembly, inspection, precision rebuild, and alignment.

Our work focuses exclusively on the mechanical side—rotors, casings, bearings, couplings, and alignment—not electrical or control systems.

We service:

- Multi-stage steam turbines (condensing, extraction, and backpressure)

- Mechanical drive gas turbines

- Turbo-expanders and boiler feed pump turbines

Whether you’re preparing for an outage, recovering from failure, or tuning a system for long-term performance, we restore your turbine’s mechanical core to spec—safely and reliably.

Why It Matters

Turbines are unforgiving. High temperatures. Tight tolerances. High rotational speeds. If a shaft isn’t perfectly aligned, a bearing is slightly off, or preload isn’t dialed in—things don’t wear out. They explode.

Common failure points we prevent:

- Bearing wipe or scoring

- Seal blowouts and steam leaks

- Casing distortion and rotor rub

- Shaft misalignment and DBSE drift

- Premature vibration and coupling failure

Turbine issues don’t give you a second warning. We make sure you don’t need one.

How We Get It Done

1. Disassembly & Walkdown

We begin with a full mechanical walkdown of the turbine system. Our techs document rotor position, casing condition, alignment status, and hardware fit before disassembly. No shortcuts—only methodical inspection.

2. Rotor Setup & Component Inspection

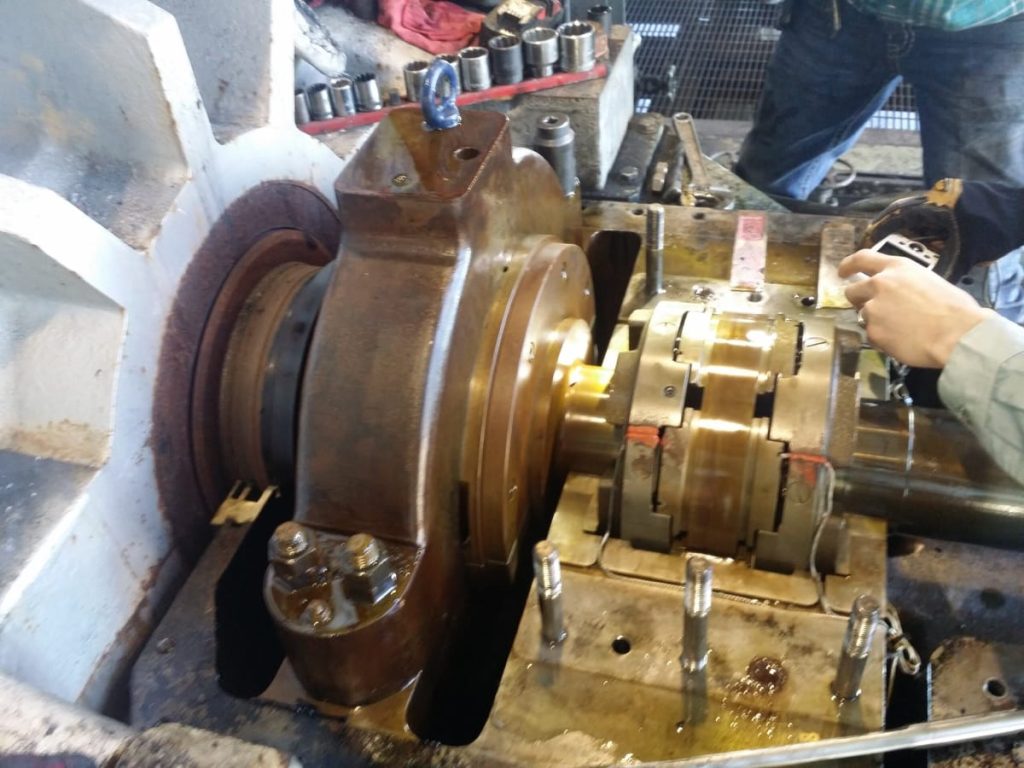

We remove the rotor, seals, and bearings and inspect each element for wear, scoring, or deformation. We measure clearances, check runout, and verify that shaft and casing interfaces are within spec.

3. Casing Reassembly & Bearing Work

We clean, prep, and reassemble the casing with exacting care—installing new bearings, seals, or other critical components as needed. We align bearing housings, ensure thermal growth targets are met, and restore preload settings.

4. Alignment & DBSE Verification

We laser-align the turbine to its driven load—generator, pump, or gearbox—verifying DBSE (Distance Between Shaft Ends) and correcting any soft foot or base distortion. Coupling faces are cleaned, prepped, and torqued precisely.

5. Startup Support & Documentation

Once reassembled, we assist with rotation checks, barring gear operation, and pre-lube or seal system confirmation. You receive documentation covering all tolerances, corrections, and mechanical findings. Our crew remains available during startup for live support.

Where We Work

Tillson turbine services are trusted by:

- Power generation stations

- Refineries and chemical plants

- Pulp, paper, and industrial manufacturing

- Boiler feed pump and steam drive systems

- Gas compression stations and turbo-expander sites

Whether your unit is base-mounted, skid-packed, or part of a larger drive train—we’re equipped and qualified to handle it on-site.

The Tillson Standard

Turbine work isn’t trial-and-error. It’s trained precision. Every bolt, every bearing, every micron of alignment must be right. Our turbine techs don’t improvise—they follow a proven system, backed by experience and mechanical intelligence.

We don’t leave until the unit is rebuilt, aligned, and startup-ready.

Call Tillson when your turbine demands more than just a wrench—it demands respect.